SITUATION

Apparatus Quo's partnership with New Edge Microbials has been to provide an external sounding board, tech advisory and project management services.

Our joint goal was to unlock better operating efficiencies, better visibility, and setting the foundations for their next stage of growth through a tech lens - an 'ERP' platform, or Enterprise resource planning platform used for both financials and operations of the business.

Post stakeholder engagement, we recapped the core goals for the ERP selection criteria to be:

- Scalable - enabling the best results and capability for NEM

- System integration and alignment - with multiple platforms and devices

- Traceability & batch tracking - from raw materials to finished goods

- Finance performance - by product, and integration to the general ledger for financial reporting

- Production Quality Assurance - the ability to meet product standards, batch documents and quality control details

- Materials requirements planning - generating material demand based on several factors

- Productivity and performance - systems and processes enabling better communication and collaboration

- Ease of use - user interface and flexibility

- Production & Supply Chain visibility - in all areas, data for reporting, manufacturing jobs, pick/pack/ship on batches

- Staff training & empowerment, roles & responsibilities and access levels

- Asset care and maintenance - considering impact on production

- Develop new, and maintain existing product ranges - including bill of material and routing templates

APPROACH

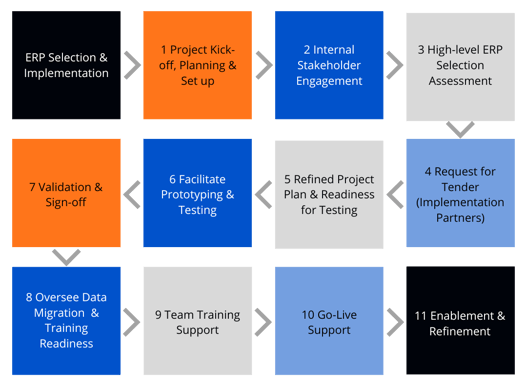

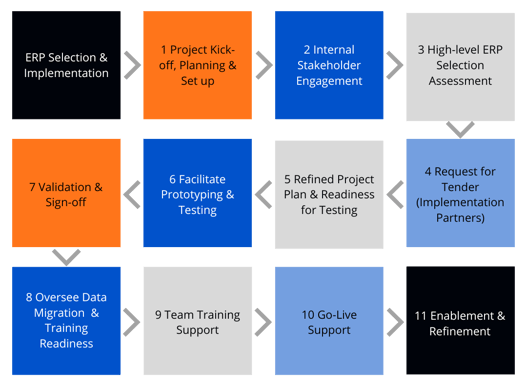

High level overview of main project phases:

Key workshops and deliverables included gathering input, defining ERP requirements, evaluating vendors, and preparing for implementation. Key steps involve workshops, vendor analysis, and financial planning. Leadership received ongoing status updates and SteerCo summaries, to facilitate decision making. Ongoing support included project management and user training preparation, ready for ERP go-live in mid-2024.

OUTCOMES

We debriefed with Damien (one of NEM's key ERP leads) in early 2024 for his thoughts on the experience:

Damien Barber, Supply Chain Manager

"Utilising Apparatus Quo provided a real advantage in selecting our new business system. Their expertise and unbiased insights streamlined the decision-making process, ensuring we implemented the perfect solution tailored to our needs. With their guidance, we saved valuable time and resources, setting a strong foundation for future growth. Thanks to their support, we're now equipped with a system that optimizes efficiency and drives our business forward."

To find out more about New Edge Microbials, check out their website here: https://microbials.com.au/

Interested in an ERP System Selection Project?

Contact us to discuss!

.jpg)